SLUICE GATES

Description

Suitable for manual operation provision may be made for power operation.Seasoned castings used for minimum distortion.Construction of ample weight and maximum rigidity. Robust sections of frame and door and scientific ribbing for additional strength.Adjustable wedge blocks to ensure positive closure of the shutter under low pressure or even back pressure conditions. Rising or non rising spindle of mild steel or stainless steel material.Foundation bolts for erecting the gate frame and operating hoist. A simple or worm geared operation hoist with gun metal nut and fitted with thrust ballbearing.Wall thimble to enable to remove the frame and shutter without disturbing concrete.

Design:

• Suitable for manual operation provision may be made for power operation

• Seasoned castings used for minimum distortion

• Construction of ample weight and maximum rigidity. Robust sections of frame and door and scientific ribbing for additional strength

• Adjustable wedge blocks to ensure positive closure of the shutter under low pressure or even back pressure conditions

• Rising or non rising spindle of mild steel or stainless steel material

• Foundation bolts for erecting the gate frame and operating hoist. A simple or worm geared operation hoist with gun metal nut and fitted with thrust ballbearing

• Wall thimble to enable to remove the frame and shutter without disturbing concrete.

• Adjustale wall brackets having vertical and horizontal adjustments

• Flush bottom closing if desired in-lieu of the bottom seating face can be provided

Specifications:

GATE FRAME: In closing grained homogeneous cast iron or mild steel fabricated with or without seating face secured by screws or rivets. Machined and hand scraped to match a similar face on door., Side guide strip of cast iron or mild steel with tapered wedges on the underside.

DOOR: of cast iron with cast reinforcements ribs or mild steel plate with vertical and horizontal stiffeners having seating face secured by screws or rivets, duly machined and hand scraped to match on then back tapered wedges to match tapered side guide strips on the frame

Integrally cast-lug to take a strong beating pin for non-rising spindle units on the integrally cast pocket to accommodate a Gun Metal nut.

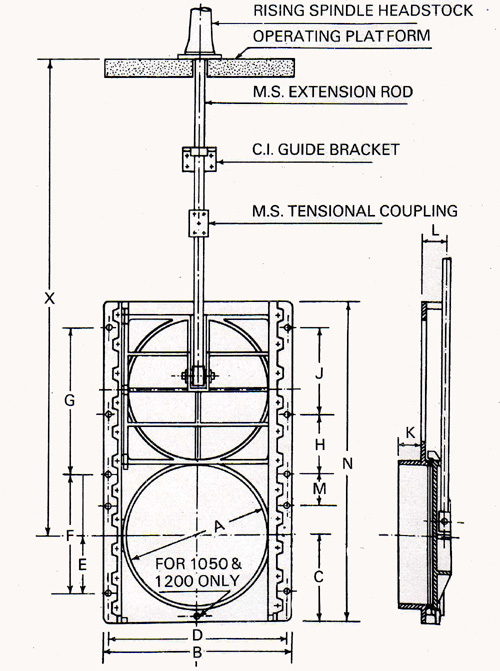

GA Drawings

Headstocks

The common arrangement for operating single-faced slice by hand operation. Depending on the nature of the spindle floor mounted headstocks are offered with extension rods, coupled and guide brackets.

• CAST IRON PILLAR

• HANDWHEEL

• GUN METAL NUT

• THRUST BALL BEARINGS

• BEARINGS GUN METAL BRUSHED ARE THE COMMON FEATURES